Recognizing Platform Lift Capacities: Essential for Reliable Lift Service

Wiki Article

Extensive Analysis on Usual Problems and Solutions in Lift Repair

In the realm of lift repair service, a careful examination of typical concerns and their corresponding options is critical to ensuring the seamless procedure and safety of these necessary upright transport systems. From the troublesome problems with elevator doors to the complex intricacies of electrical breakdowns, a myriad of challenges can pester lift capability (lift breakdown). As we explore the intricacies of lift upkeep, a comprehensive understanding of these problems and the efficient approaches for resolving them becomes an important facet of ensuring optimal lift performanceElevator Door Issues

One of one of the most typical obstacles encountered in lift maintenance is attending to lift door breakdowns. The smooth procedure of lift doors is crucial for passenger safety and security and performance. A defective door can bring about hold-ups, aggravation, and also potential risks.Elevator door issues can stem from various elements, such as malfunctioning door sensing units, misaligned doors, worn-out rollers, or problems with the door operator mechanism. These breakdowns can result in doors not opening or closing effectively, obtaining stuck midway, and even closing too rapidly, posturing a danger to passengers entering or leaving the lift.

To resolve lift door malfunctions efficiently, upkeep service technicians need to conduct normal examinations, oil relocating parts, adjust door timings, and replace damaged elements immediately. Furthermore, executing preventive upkeep routines can help recognize and deal with potential door concerns before they rise. By prioritizing elevator door maintenance and without delay attending to malfunctions, structure owners can ensure the effective and safe procedure of their lifts.

Electric Malfunctions

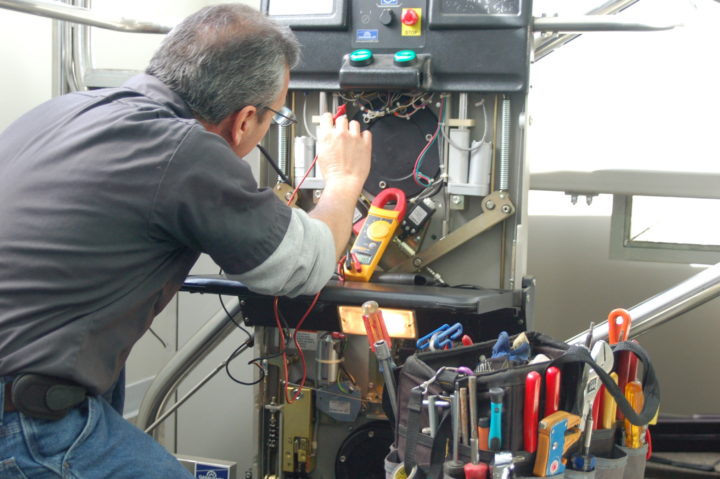

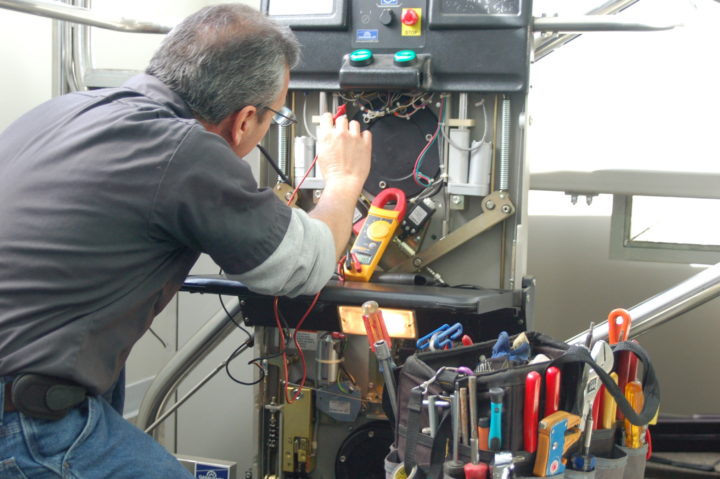

Resolving electric breakdowns in lifts requires extensive analysis assessments and accurate troubleshooting techniques to make certain the risk-free and trusted performance of the lift system. Electrical malfunctions can manifest in different means within a lift system, ranging from concerns with the control panel, damaged electrical wiring, power supply troubles, to issues with interlocks and sensors. When coming across electrical breakdowns, it is important for upkeep personnel to comply with an organized technique. This includes inspecting the power supply to the lift, checking circuitry for any indications of damages or wear, and checking the capability of key components such as the control board and emergency situation quit switch. Using diagnostic devices such as multimeters and circuit testers can assist in pinpointing the source of the electric breakdown accurately. Furthermore, making certain that all electric connections are protected and up to code is essential in avoiding future malfunctions. By attending to electric issues quickly and efficiently, lift service technicians can keep the safety and security and performance of elevator operations.Hydraulic System Troubles

Furthermore, hydraulic pump failures can take place as a result of concerns such as overheating, click here for more too much wear, or absence of appropriate maintenance. A malfunctioning pump can cause the lift not being able to produce enough hydraulic stress to operate efficiently. Normal evaluation, maintenance, and prompt replacement of hydraulic components can stop these issues and guarantee the smooth performance of the lift system. Correct training for maintenance employees on hydraulic system repairing and repair service can also assist in addressing these troubles without delay and successfully.

Control System Glitches

Control system breakdowns can interfere with the smooth operation of lift systems and pose safety dangers if not without delay addressed. These problems typically come from problems such as electric failures, software bugs, or sensing unit malfunctions. When the control system fails to connect successfully with the lift parts, it can result in unpredictable activities, unanticipated stops, or full closures. One usual trouble is the misalignment of sensors, leading to inaccurate flooring progressing and door operations. Electric failures, consisting of power rises or damaged wiring, can additionally cause the control system to malfunction.To attend to control system glitches, lift repair service technicians have to conduct detailed diagnostics to determine the source of the issue. This may involve checking the electric links, adjusting sensors, or reprogramming the control software program. Regular maintenance checks can help prevent these glitches by identifying prospective concerns prior to they intensify (platform lift dimensions). By without delay resolving control system breakdowns, lift drivers can guarantee the safety and reliability of their systems for passengers and prevent costly downtime.

Security Includes Concerns

In guaranteeing the optimal capability of lift systems, caution towards the honesty of safety and security functions comes to be browse this site extremely important adhering to the identification and resolution of control system glitches. Safety and security attributes in lifts are designed to prevent mishaps, injuries, and breakdowns. Dealing with safety and security attribute worries quickly can considerably reduce the risk of mishaps and improve the overall safety of lift procedures.Verdict

Finally, usual problems in lift fixing include elevator door problems, electrical breakdowns, hydraulic system troubles, control system problems, and safety and security features problems. It is critical for upkeep groups to attend to these problems immediately to guarantee the secure and effective operation of elevators. By carrying out proper upkeep procedures and regular inspections, these issues can be recognized and settled successfully to stop any type of disturbances in elevator function.

In guaranteeing the click here to read optimal functionality of lift systems, alertness towards the stability of safety features becomes vital adhering to the identification and resolution of control system glitches - lift repair.In final thought, common problems in lift repair work include elevator door issues, electric malfunctions, hydraulic system troubles, control system glitches, and security attributes concerns

Report this wiki page